7 Functions:

-Chamfering

-Grooving

-Bevelling

-Centering

-Optical tracing

-Polishing

-Lens thinning

Edging speed improved by 30%

The roughing and finishing process are united. Compared to last generation L3 edger, the same

edging process is 40 seconds faster, and the efficiency has been enhanced greatly!

BETTER PERFORMANCE

Optical tracing

Patented optical tracing technique, with lens balanced on convex side for tracing. 2.3-second fast lens, demo lens and pattern shape capture. Also supports frame curvature capture.

Dual job mode

Rely on the intelligentized edging bench and cutting-edge algorithm, the LE-5600 edger can realize seamless dual-job task flow. Optical scanning, shape capturing with camera, centering and blocking can be finished during lens edging in process, enhancing the edging efficiency significantly.

High base curve lens processing

The 90mm diameter small wheel can ensure the edging effect for high base curve lens. The maximum curve processable is up to 1,200, fulfilling fitting requirements of sunglasses etc.

EXCELLENT EDGING EFFECT

Edging mode for special lens

Intellective edging system, with built in safety mode, supports processing of prism lens and special slippery lens, reducing lens distortion due to the pressure during lens edging, protecting lens film and ensuring high-efficiency safety edging with no damages for the lens.

Auto grooving and lens thinning with

chamfer

The intelligent groove position and depth setting function improves the edging efficiency for grooving process and chamfering process for lens thinning, realizing the perfect balance between aesthetics and thickness, making the edged lens thinner, lighter and more beautiful.

Optional waste disposal solution

Optional pretreatment device can absorb the pungent odor generated during lens edging process, improving the air quality, and separate the residual of lens edging process more completely from the edging fluid.

NO AXIS SHIFT DURING

EDGING PROCESS

Anti-slip tests with more than 60 types of lenses

In-depth analysis of the anti-slip coatings with various lenses, continuous verification of

the edger reliability for 5 years, while ensuring improvement of edging efficiency, it also at

the same time guarantees no axis shift during edging process for slippery lens.

High precision press sensor

Kg level precision for lens edging press control, and real-time accurate monitor of the

press change keep the clamping press within stable level.

Anti-slip design and technique

Special clamping chuck design and electromagnetic induction clamping force control

technology allow clamping on lens optical center or geometry center optional, reducing

off-center effect, improving edging efficiency, optimizing edging speed while ensuring no

axis shifting during lens edging process.

Specifications

Optical tracing:Optical tracing for automated shape recognition of lens,

demo lens, pattern and frame line

Centering: Parallax free to fulfill centering on the optical center and

geometrical center for almost all kinds of lenses

Shape modify: Supports pattern enlarge and minification

Data storage: Data base for 3,000 jobs

Lens material detection: Can process lens with material PLA (CR39), PC, MHI and TRI.

Edging process for lens with special material can be user-defined for better edging accuracy

Lens scanning: 3D dynamic lens scanning

Bevel finishing: 3D preview, bevel position can be manually adjusted Processing range for finishing bevel height: 0.3mm-0.8mm

Grooving: Groove depth and width configurable

Groove depth adjust range: 0.1mm- 0.8mm

Groove width adjust range: 0.6mm- 1.2mm, Minimum thickness for groove walls: 0.3mm

Polishing: Flat and bevel

Polishing range for flat finishing: 0- 10.8mm

Polishing range for bevel finishing: 0.3mm- 0.8mm

Screen: 10.1-inch color touch screen

Size: 716W*555D*460H

Weight: 75kg

Voltage: 220V/230V, 50/60H

Power consumption: 1,000W

Accessories

Accessories

AI Eyeglasses

AI Eyeglasses

Alcohol Bottle

Alcohol Bottle

All collections

All collections

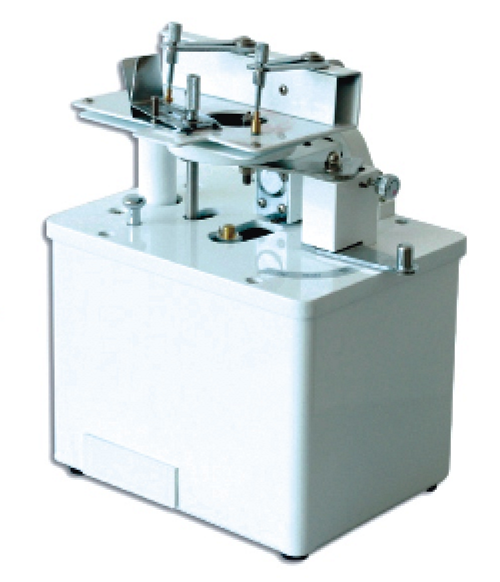

Auto Lens Edger

Auto Lens Edger

Auto Refractometer

Auto Refractometer

Beam Splitter

Beam Splitter

Belt Series

Belt Series

Bench Vice

Bench Vice

Blade For Auto Groover

Blade For Auto Groover

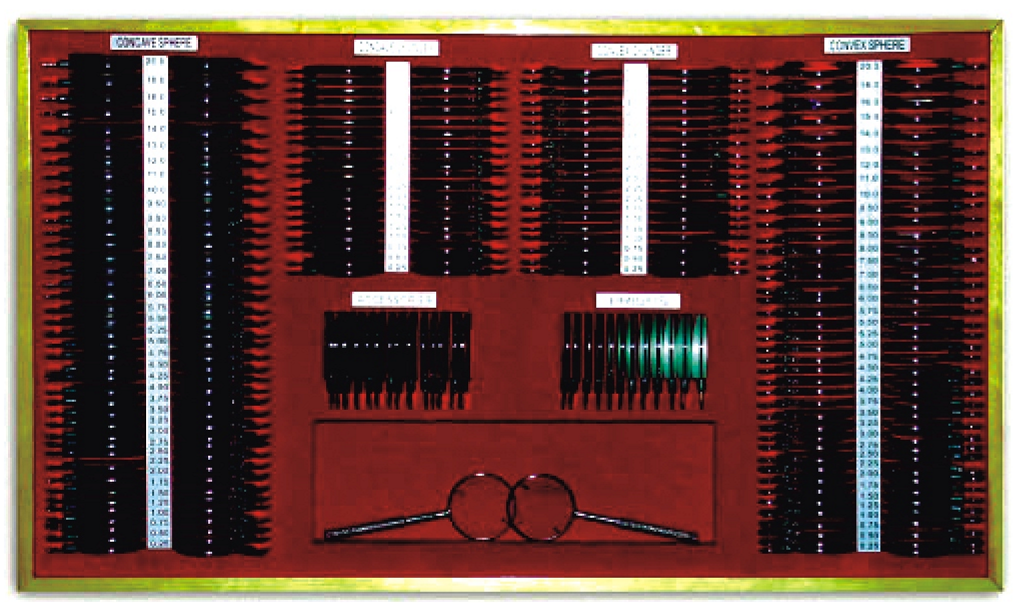

Board Lenses

Board Lenses

Bulb Series

Bulb Series

Carry-On

Carry-On

Casing

Casing

Chart Monitor, Projector, and Visual Chart

Chart Monitor, Projector, and Visual Chart

Chuck

Chuck

Cleaning Solution

Cleaning Solution

Cloth

Cloth

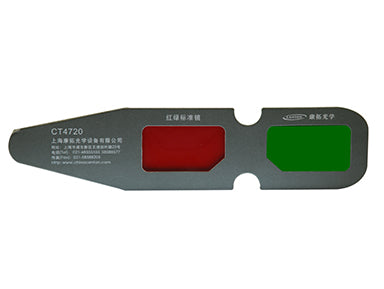

Cross Cylinder

Cross Cylinder

Cutter

Cutter

Doctor Chair

Doctor Chair

Dressing Stick

Dressing Stick

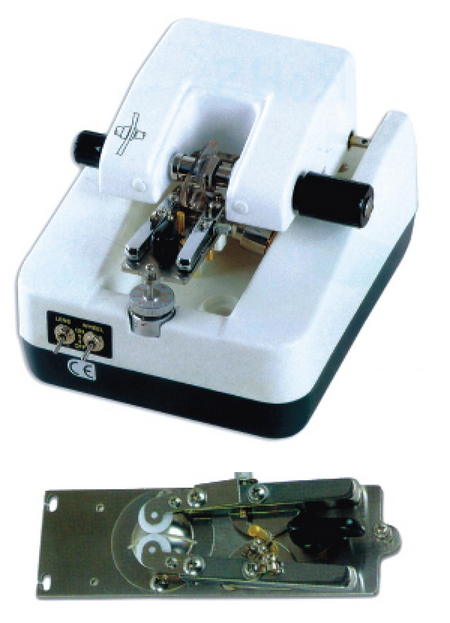

Drilling Machine

Drilling Machine

Drilling Machine Tools

Drilling Machine Tools

Dry Eye Analyzer

Dry Eye Analyzer

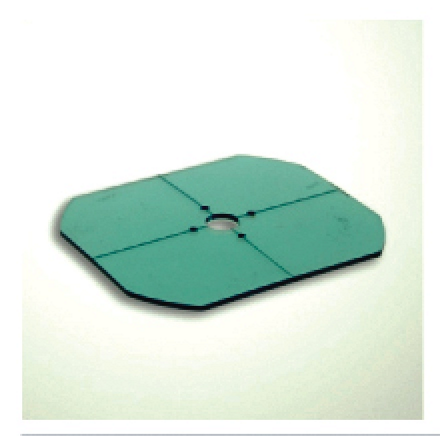

Edging Tape/Pad/Sticker

Edging Tape/Pad/Sticker

Edging-Machine

Edging-Machine

EEP

EEP

Eyeglasses Cabinet

Eyeglasses Cabinet

Eyeglasses Case

Eyeglasses Case

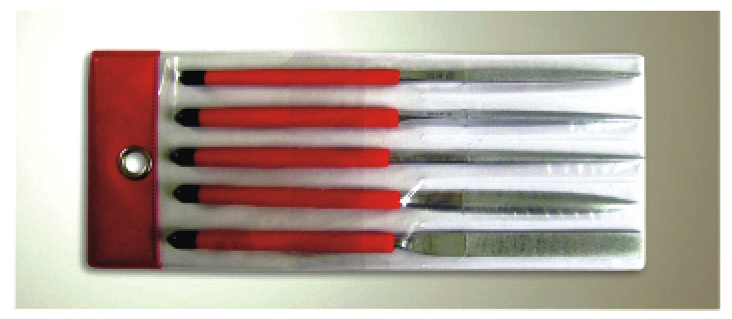

Files

Files

Flipper

Flipper

Floor-Stand

Floor-Stand

Frame Heater

Frame Heater

Gift Bag

Gift Bag

Groover

Groover

Hand Edger

Hand Edger

Hand Lamp

Hand Lamp

Hole Gauge

Hole Gauge

Job Tray

Job Tray

Lens Clip

Lens Clip

Lens Tester

Lens Tester

Lensmeter

Lensmeter

Mirror Series

Mirror Series

Monocular

Monocular

Motorized Table

Motorized Table

Mould

Mould

Near Vision Chart

Near Vision Chart

Near Visual Aid

Near Visual Aid

New Arrival

New Arrival

Nose Pad

Nose Pad

Occluder

Occluder

Ophthalmic Chair And Stand

Ophthalmic Chair And Stand

Ophthalmoscope, Retinoscope

Ophthalmoscope, Retinoscope

Optical Tool

Optical Tool

Optician Tools

Optician Tools

Optometry & Ophthalmic Instruments

Optometry & Ophthalmic Instruments

PD Meter

PD Meter

Perimeter/Visual Field Tester

Perimeter/Visual Field Tester

Phoroptor

Phoroptor

Pliers

Pliers

Pliers & Screwdrivers & Tools

Pliers & Screwdrivers & Tools

Pliers Stand

Pliers Stand

Polisher

Polisher

Poloshing Cerate

Poloshing Cerate

Prisms

Prisms

Promotions

Promotions

Protractor

Protractor

Radian Apparatus

Radian Apparatus

Refurbishment

Refurbishment

Remote-system

Remote-system

Screw Tools

Screw Tools

Screw-Bundle

Screw-Bundle

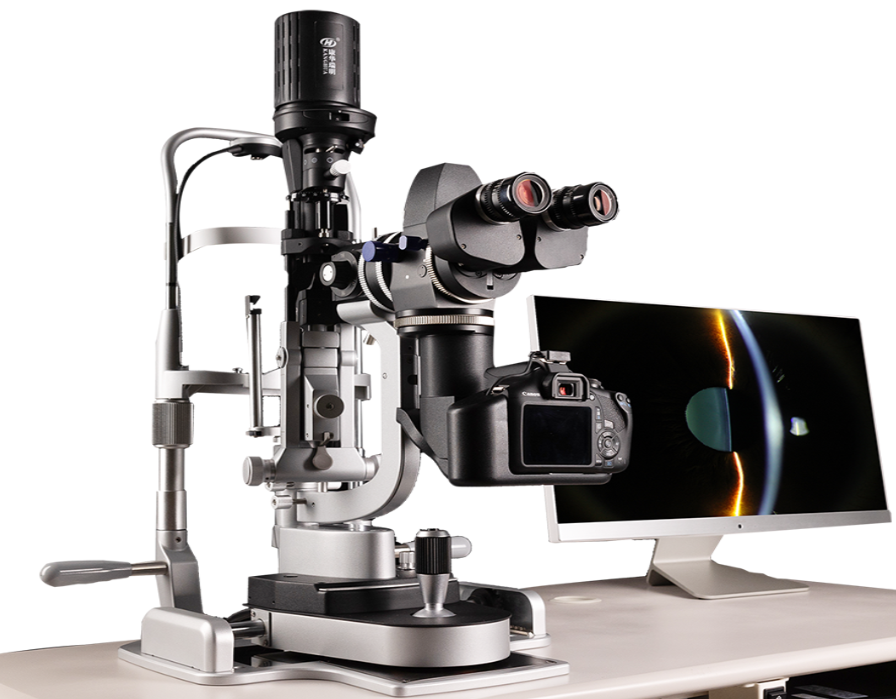

Slit Lamp

Slit Lamp

Supplies & Accessories

Supplies & Accessories

Temple

Temple

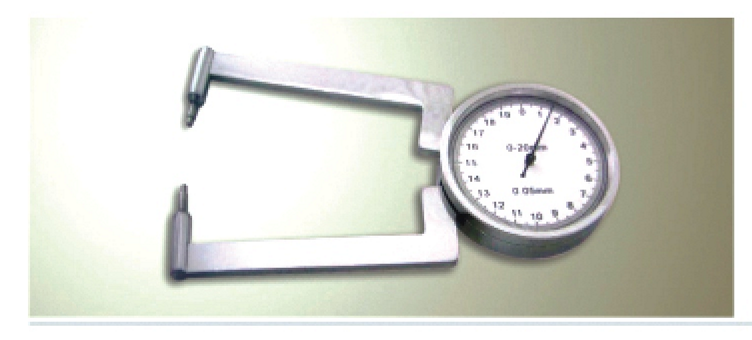

Thickness Apparatus

Thickness Apparatus

Tinting Machine

Tinting Machine

Tool Set

Tool Set

Tools Kit

Tools Kit

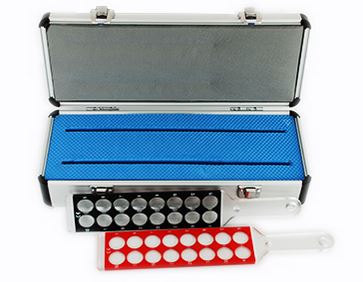

Trial Lens Set

Trial Lens Set

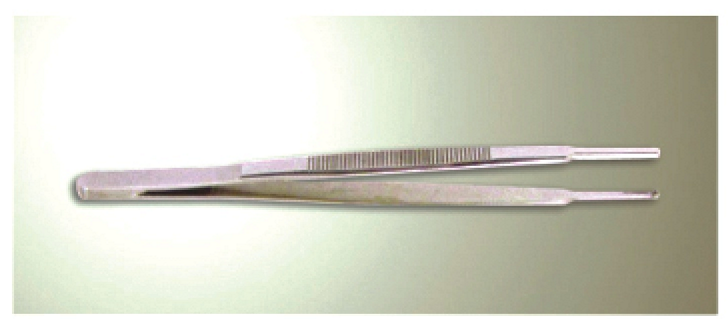

Tweezers

Tweezers

Ultrasonic Cleaner

Ultrasonic Cleaner

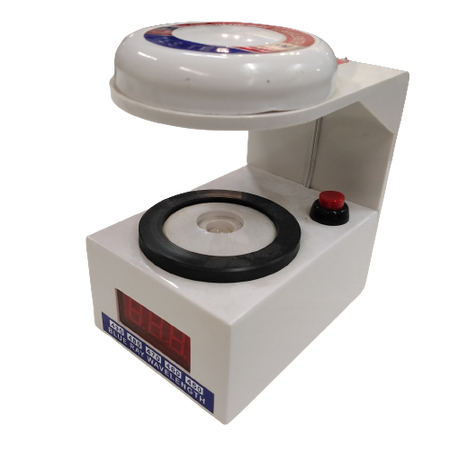

UV Tester

UV Tester

Wall-Mount

Wall-Mount

Warranty

Warranty

Wheels

Wheels